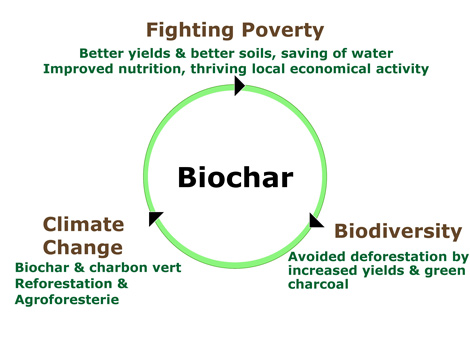

A charcoal making machine is a special type of furnace that is used to produce charcoal. Charcoal is a carbon-rich material that is made by heating wood or other organic materials in the absence of oxygen. It has a number of advantages over wood fuel, including a higher energy density, a lower moisture content, and a lower ash content. In addition, it produces less smoke and heat when burned, making it ideal for use in grilling and barbecue applications. As a result, charcoal making machine for sale has become increasingly popular in recent years.

Types of Charcoal Making Machines Available For Sale

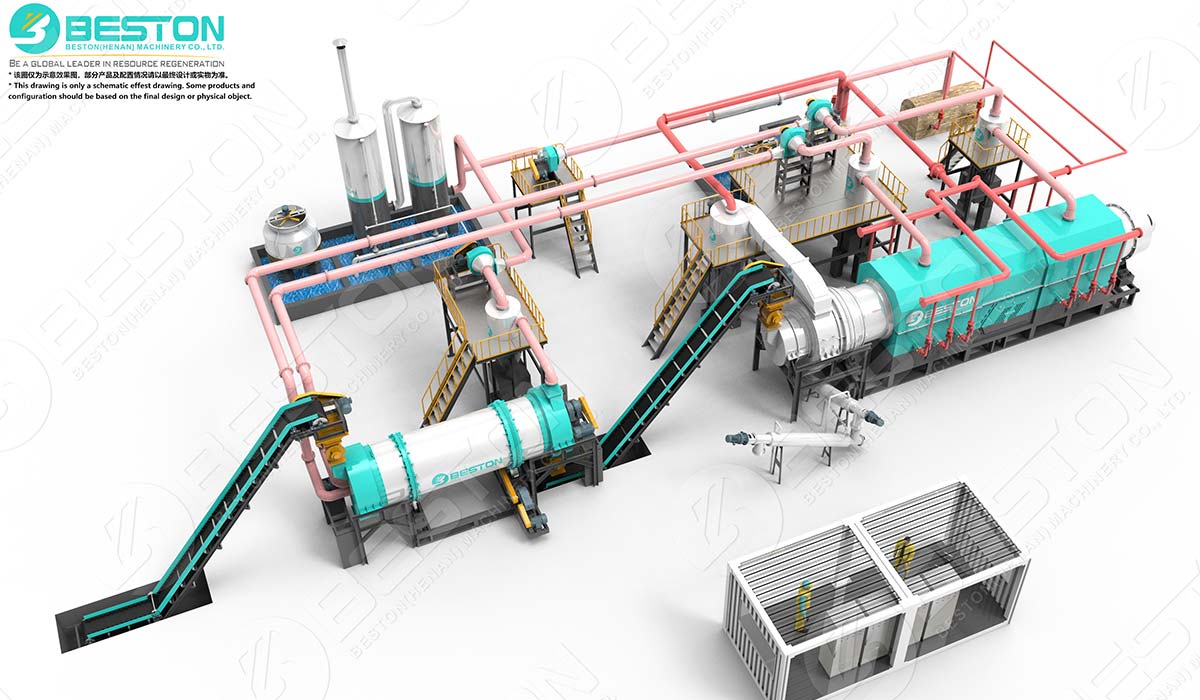

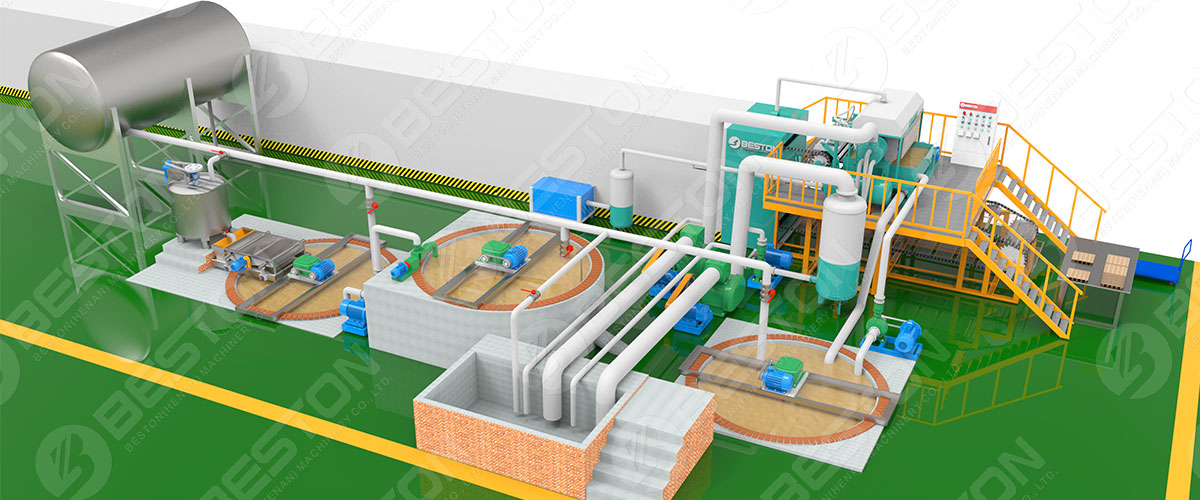

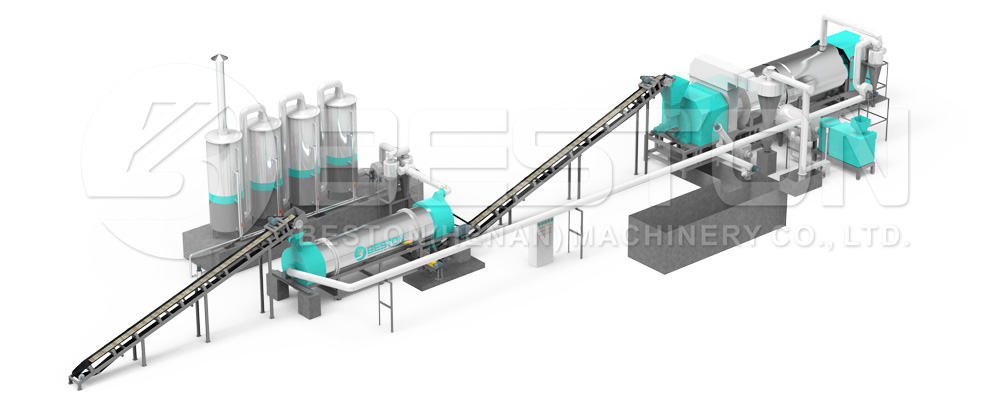

There are a number of different types of charcoal making machines on the market, each with its own set of benefits. The most popular type of charcoal making machine is the downdraft kiln, which uses airflow to draw the smoke and heat away from the wood as it burns. This type of kiln is very efficient and can produce large amounts of charcoal in a short period of time. Another popular type of wood charcoal making machine is the updraft kiln, which uses a chimney to draw the smoke and heat away from the wood. This type of kiln is less efficient than the downdraft kiln but can still produce high-quality charcoal. Finally, there are some small portable models that can be used to produce charcoal at home. These units are less expensive than commercial models but are still capable of producing high-quality charcoal.

Buying A Charcoal Making Machine

Anyone who is thinking about purchasing a charcoal making machine should consider four important factors before making a decision.

● First, you need to think about the type of wood that you will be using. Different woods produce different amounts of charcoal, so it is important to choose a machine that is designed for the specific type of wood being used.

● You also have to consider the size of the machine. A larger machine will be able to produce more charcoal, but it will also be more expensive.

● It is also crucial to think about the quality of the biomass carbonization machine. The better the quality, the longer it will last and the more charcoal it will be able to produce.

● Finally, you need to have a budget to buy the machine. This will help to compare the price of the machine available for sale with your budget so that you can choose the best one within what you can afford. Charcoal making machines can vary significantly in price, so it is important to compare the features and functions before finally settling for one. By taking all of these factors into consideration, you can find the perfect charcoal making machine for your needs.

Although the charcoal making machine is a great investment, it is important to remember that not all machines are created equal. Make sure to do your research before investing in a machine and don’t forget to read the reviews of other customers. With proper use, the biochar production equipment can provide years of service.